distribute worthwhile and interesting information to help industry generate more profit.

Sandy Munro to Speak at CPI Symposium - May 14th

Continuous Improvement approaches of the last few decades are being hailed as “necessary to compete” in an expanding global marketplace. But, implementing these solutions – and getting the results that please shareholders, customers and employees alike – doesn’t happen by magic. How does it happen? What are people and their organizations doing to turn the “common sense” solutions of Lean, The Theory of Constraints (TOC), and Six-Sigma into real results?

These are the questions to be answered by the speakers featured in the Continuous Process Improvement Symposiums. The annual CPI Symposium will be the only nationwide educational and networking event available to practitioners, consultants and academics that specifically covers solutions from all three major approaches of Lean, TOC, and Six-Sigma. This event is designed to offer practical and relevant information on the latest developments in applying these three methods in an integrative approach, enabling organizations to achieve breakthroughs in competitive advantage.

As Francis Bacon said in the 16th century, "Knowledge itself is power."

If this is true, then why would we not bring as much knowledge as possible up front to the concept development of a product design?

"We do," I have heard. "CAE (Computer Aided Engineering) has been available for 35 years bringing much more knowledge through virtual analysis." This is true, and these advances have been required to engineer products to the levels of performance and durability demanded in today’s market. Most everyone will agree to its importance and that CAE is vital to today’s climate.

The concern, however, is that the product concept design, for the most part, is completed before the CAE refinement happens. I am talking about the space that comes before CAE and development and validation.

"Oh, I see," you say. "You mean market and customer features analysis. We have a whole department dedicated to this." Again, true, but this is not the step that I am referring to. I am most concerned with the gap between the market analysis and the engineering. This is what I am referring to as the "product concept design."

Each issue of The Munro Report will feature one of Munro's Design Principles. Implementation of these principles will help maximize the profitability of your product through its design.

#3 Avoid Expensive Secondary Fastening Operations

At Ford Motor Company, a study perfromed by Sandy Munro revealed that 70% of warranty failures, from rattles in the intrument panel to wheels falling off, occured due to problems with fasteners.. 90% of Catastrophic failures could be directly attributed to threaded fasteners.

There are as many ways to fasten two parts together as there are designs. If you ask an assembler, he’ll tell you that, "He can build anything". If you ask suppliers they tell you, "Their product can do anything". If you ask service they’ll tell you, "They can fix anything", that's what the big tools are for. If you ask the customers, they say, they "just want it to work". That's reliability and that only comes from simplicity. Simply put, the best fastener is no fastener at all. Our design drive will be to eliminate loose fasteners as much as possible.

If we can’t eliminate loose fasteners, then let’s remember that they will be the weak link and we should purchase the best. If tools are necessary, let’s make sure they are standard and easy to use.

The following descriptions are for the most common forms of fastening. If fastening is required, the right type of fastening for the function, life, environment and customer interface should be used.

Engineer the joint; don’t just screw it together. Remember, most failures in products come at the “gray area”... the point where two parts come together.

Snap Together

If engineered correctly, this is your best choice from every standpoint. The problem is that snap fits are not easy or quick to design. There are many plastic snap fit design guides (see reference books), but few when it comes to sheet metal, aluminum, extrusions, or machined steel. Don’t forget a snap fit joint can be designed to be easy or impossible to service. The choice is yours.

Press Together

Press fits are used to secure two parts together by means of a slight interference between two mating parts. The method should employ some type of tool such as a fixed arbor press or hammer. (Press fit charts are located in the SAE Design Handbook.) Another type of friction securing is freeze fitting. Dowels, gears and bearings that fit into housings are also examples of press fits.

Hand Staple

A hand staple gun is used mainly in the assembly of seats, furniture and in general building construction. The tools can be powered or not.

Screws

Contrary to popular thought, screws are not friction devices and because of their 60 degree included angle, they would be more appropriately named "UNFASTENERS". Screws were engineered for easy removal, not for long term staying power. The only three ways to get them to stay in place involves a secondary expense.

Method One: Proper rundown of a threaded fastener involves the application of torque coupled with angle monitoring. This ensures that the fastener has been put into the “plastic state” which is to say into yield, but not beyond the limit of elasticity. The process is very reliable and repeatable and will give excellent results as long as the screws are designed and received from a supplier at a 6 sigma quality rating.

Method Two: Glue the fastener in with Loctite™.

Method Three: Use spiralock taps which turn the standard threaded fasteners into a friction device by using a locking angle on the threads.

When Specifying Threaded Fasteners, They Should Have:

1. A clean dry mechanical plated finish with a flange style head to eliminate waste (get rid of washers).

2. A dog point end to aid in starting the thread.

3. A reject rating of less than 3/1,000,000 parts (6 sigma).

4. A good shank to head ratio (1.5 to 1).

5. A head design that lends itself to quality fastening. Flat head screws are the worst choice; they are the most unreliable for clamp load.

6. Driver points that lend themselves to accurate torque monitoring.

Remember, the biggest enemy of high quality is a fastener. When creative designs can not eliminate all fasteners from your assembly, be sure to use an engineered solution.

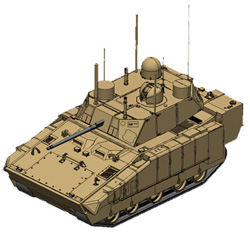

Munro & Associates is currently working with GDLS on the manned vehicle for the Future Combat Systems program. Munro participated in a one day march on Capitol Hill to spread the news of how important FCS is to our Army and our manufacturing economy. We are pleased to report that Senators Levin and Stabenow as well as Representatives Miller and Knollenberg understand its importance to our Nation and our Michigan manufacturing businesses and are 100% behind it.

The recipients of this years Munro & Associates Award are:

Cadet Richard Simmon - Northern Michigan University - Army

Cadet Thomas Sanger - Michigan Tech University - Army

Cadet Christopher Cooper - Michigan Tech University - Air Force

Cadet Kevin Loose - Western Michigan University - Army

Cadet Sebastian Jacobi - Michigan State University - Army

Cadet Stephen Sutara - Michigan State University - Airforce

Cadet Benjamin Schmidt - Eastern Michigan University - Army

Cadet Amada Gunther - University of Michigan - Army

Cadet Tatiana Merideth - University of Michigan - Air Force

MIDN Ryan Hall - University of Michigan - Navy

MIDN Andrew Larson - Great Lakes Maritime Academy - Navy

To request more information about Munro and Associates, Inc. Click Here

All photos and information copyright Munro & Associates, Inc. 2008