distribute worthwhile and interesting information to help industry generate more profit.

Auburn Hills, MI, May 13, 2008 – With their sights set on intensifying manufacturing companies’ product cost reduction efforts while increasing efficiencies and profitability, two leading suppliers in the fields of Product Lifecycle Costing and Lean Design® announced their joint alliance today.

U.S. manufacturers are struggling to compete in a global market. This alliance provides invaluable resources to fine tune communication and transparency between engineering, operations and financial leadership so they can wring out every dollar to be competitive. Customers will have the unique ability to see real time financial effects of product and process engineering tradeoffs with FACTON and Design Profit® software while employing Munro & Associates’ unparalleled success in Lean Design. The results: for the first time, companies will be able to truly link engineering and operational progress with financial monitoring in order to optimize their margins.

Munro Customer Success Story

Each issue of The Munro Report will feature one of Munro's Design Principles. Implementation of these principles will help maximize the profitability of your product through its design.

#4 Design Out Handling Problems

Not all products and parts can be assembled right away. Some require an extra step, like screwing. An operator needs to get the part, put the part in its place, then fasten the part to rest of the assembly. Additonally, not all fastening operations can be done by hand like a jar lid. Sometimes a tool will be needed. Throughout the assembly proccess, it is sometimes nescesary to perform non-value added operations such as inspections, moving a part, or causing the operator to move. These extra steps take time, cost money, and create opertunities for poor quality.

In this issue of The Munro Report, we will define common operations required for the assembly of most products. In Munro's Lean Design method, each of these operations recieves a quantified penalty that helps reveal to our customers the Total Accounted Cost of their product. The severity of the penalty is determined by the time it takes to complete each operation and the likley hood of getting it right the first time. It should be your goal to design-out as many of these tasks as possible from the assembly of your design to ensure a profitable, high quality product.

We will address these tasks in two sections; Get - The Part to Operator Interface - and Put - The Part to Part Interface.

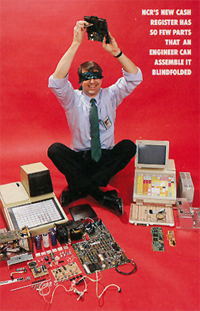

By reducing the number of components and designing out handling problems, William Sprague of Munro & Associates accomplished an 85% reduction in parts, a 65% reduction in the number of suppliers and 75% reduction in assebly time for NCR Corp.'s 2670 electronic cash register. The register is assembled without a single screw can be put together by a blindfolded operator!

Heartiest congratulations to Dr. Susan Okray, Director of Benchmarking for Munro & Associates. We have just received news that Susan successfully defended her dissertation titled “Laser Weld Bonding of Aluminum Alloy 6013-T6” at Lawrence Technological University.

Her findings illuminate the importance of a new hybrid joint which combines laser welding and adhesive bonding to generate higher joint shear and peel strengths as compared to conventional riveted, laser welded or adhesive bonded aircraft joint constructions. The results of her research demonstrate that this new LWB process is a viable joining alternative capable of producing joint strengths which exceed target rivet joint strength requirements. These findings have encouraged Munro & Associates to continue the LWB development work and pursue licensing agreements and patents on the process.

This exciting new joining process has the potential to provide a new aircraft joining alternative which can significantly reduce the cost of building airframes.

To request more information about Munro and Associates, Inc. Click Here

All photos and information copyright Munro & Associates, Inc. 2008