please add editor@munroreport.com to your email address book, personal white lists, or buddy list.

distribute worthwhile and interesting information to help industry generate more profit.

With new manufacturing quality scandals coming out of China on a regular basis, ranging from melamine found in food products to inferior grade steel that breaks down easily, isn't there a smarter way to reduce manufacturing costs without facing the quality question mark of China? Well, perhaps there is a manufacturing gem hidden in a place that is much closer than Beijing.

For years the Detroit Big 3 has kept a secret access to comparatively inexpensive and highly skilled Machine Tool Die and especially Mold Makers with Millions of available machine hours. One component of this group, CAMM (Canadian Association of Mold Makers), has consistently applied itself to supply quality molds to auto-industry in North America.

In this changing economic environment, where cost reduction is key, the shops that make up CAMM are stepping up to the plate and showcasing their talent and abilities, and more importantly their cost effective solutions to supply chain needs.

Although they have been highly utilized by the auto industry for years, more and more shops have made the venture into aerospace, achieving their AS 9100, and some have even won supplier awards such as Valiant Tool and Mold who won the 2007 Boeing Supplier of the year award for the Non-Production category. Many are also getting involved in the manufacture of auxiliary equipment for medical and a few even have defense contracts. However, diversification is basically mandatory in today's world, so to showcase their capabilities and let the world know about the big 3s secret supply chain ace in the hole, CAMM is holding the first trade show of its kind at the newly built convention center in Caesars Windsor November 18 and 19.

It will feature over 80 Mold, Tool and Die shops from all over Quebec and Ontario, where most of the mold making takes place in Canada. Most of these companies are located on or near the 401 corridor which will basically take you from Montreal, Quebec to the US/Canadian Border city of Windsor, Ontario (bordering with Detroit, Michigan) in a less than half a day, giving the ability to move equipment and materials quickly and easily to all major North American transportation routes including ship, land, sea, and air.

This highly influential area accounts for a large and affluent economic area reaching 125 million consumers, 90% of vehicle assembly plants, $6 Billion in aerospace revenues, 97% of all mold manufacturing in Canada, and 60% of both Canadian and U.S. manufacturing capabilities which are all concentrated within one days drive.

Although not well known in Japan and Europe still (although Windsor-Essex was voted 2007/2008 #1 Best Small City for Investment in North America by the prestigious Financial Times, London, UK), CAMM companies offer a unique advantage as the exchange rate, due to the strength of the Euro v. the Canadian dollar, creates savings in supply chain costs that are competitive with China, especially when you consider that the quality in this region is equivalent to any European shop, as many shop owners are German machinist ex-patriots who have transplanted their skills in Canada.

Well, there you have it; the secret is out. The only question now is.are you going to miss out?

Written by Alistair Munro

About CAMM:

The Canadian Association of Mold Makers is an industrial organization consisting of mold makers and their integrated mold making network which includes over 100 shops. For more information and tickets to the show, contact Diane Deslippe, executive assistant, at CAMM ( 519)255-7863 or find contact email at http://www.camm.ca or Alistair Munro at (519) 551-8880 or via email at alistair@leandesign.com.

Newly approved provincial funding will enable Windsor/Essex machine, tool, die and mold companies to be trained in Lean Design® and Lean Manufacturing to make them more competitive in a global marketplace.

Training will be delivered by Lean Design Canada and the funding will accommodate 20 companies, on a first-come, first-served basis with some already paid and signed up such as Dan Moynahan of Platinum Tool and CAMM. This training will help not only our company become more competitive, but also help to put Windsor shops on the global map as far as being a Lean community," says Dan. The deadline for submission is December 15, 2008.

"This program will provide the necessary tools for local suppliers to retain their existing automotive business while reducing costs and offer competitive approaches to capitalize on opportunities in new markets such as aerospace," said Tracy Pringle, director of business retention and expansion with the Windsor Essex Development Commission.

The funding has been provided by the Ministry of Economic Development and Trade through a Communities in Transition grant where half of the training will be paid by the government of Ontario.

"The techniques and strategies that the selected companies will be taught are the same ones that we have used to assist hundreds of companies around the globe, save billions of dollars," said Alistair Munro, Lean Design's business development manager.

"The result of past training has allowed companies to turn around their operations resulting in significant results for these clients."

Interested companies are encouraged to contact the Windsor Essex Development Commission as soon as possible in order to take advantage of this limited time opportunity. For further information, contact Tracy Pringle at the WEDC at (519)255-9200, ext, 2229.

10 Best Practices for Design From the Design Profit Silver Book

Each issue of The Munro Report will feature one of Munro's Design Principles. Implementation of these principles will help maximize the profitability of your product through its design.

Lean Design Principles - 07

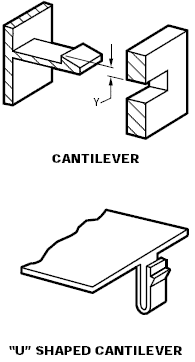

Design The Parts To Fixture Themselves One To Another - Design for B.O.B. (Blindfolded One-Armed Builder)

You ALWAYS want to create a design that can be assembled with as much ease as possible. That means designing parts that will fixture themselves in place without requiring fancy tricks.

Let’s face it, most fasteners are doomed to fail and should be used only whenever unavoidable. More importantly, in the case of threaded fasteners (which tend to work more like threaded UN-fasteners), they are generally notorious for being difficult to align during assembly. This makes fumbling and dropping a constant reality of assembly line workers which adds to waste in both part cost and assembly time. To avoid this, engineers and designers need to design with a "snap fit" in mind. Not only does this comply beautifully with the self fixturing principle, but also due to the nature of "snap fits", it also complies with the "easy to self locate" rule.

Remember, all designs should be created with B.O.B. in mind, which specifically means that it should be designed to be assembled by a Blindfolded One-armed Builder. If you design with this strict criteria in mind, your designs will always be elegant and easy to assemble.

To request more information about Munro and Associates, Inc., please email Joseph Feord

All photos and information copyright Munro & Associates, Inc. 2008

1749 Northwood Drive Troy, MI 48084

http://www.leandesign.com | Phone: (248)362-5110