To ensure that you continue to receive The Munro Report,

please add editor@munroreport.com to your email address book, personal white lists, or buddy list.

distribute worthwhile and interesting information to help industry generate more profit.

There is plenty of discussion around cost estimating these days and rightfully so. Today’s economy and discerning global consumers demand value. Global competition continues to increase and the pressure is on firms to be more innovative and responsive with accurate cost estimates. Producers of product must be on the "cost" mark, right the first time to stay in the race.

With all that is riding on accurate costing systems many companies still rely on quick rough order of magnitude (ROM) cost approximations where estimators look at past part costs and attempt to reason forward. This type of estimating is called Proportioning Historical Costing. The costs of a future product or process are determined from those of a similar existing products and processes to which proportional coefficients are applied. This method is typically used when there are no perceived important technological differences between the two products or processes or when a rough order magnitude estimate is required. The assumption is that the historical cost is accurate. This is a dangerous assumption that can inadvertently but quickly erode any profit picture. Proportioning Historical Cost estimating is perilous because it is not just minor part changes that drive costs. Underlying cost assumptions change with the economy and these too must be taken into consideration.

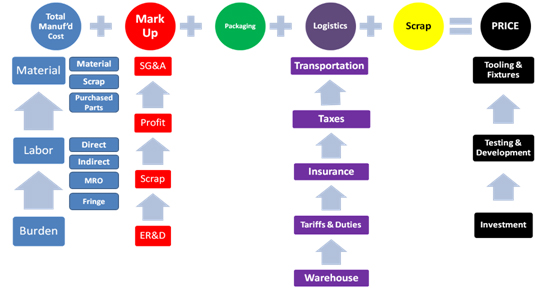

For this reason cost estimating is a continuous, cyclic process and depending on the accuracy desired two major costing methods are used. The most comprehensive and preferred costing method involves understanding all the steps and operations required to deliver a product "Total Accounted Should Cost" estimate. This process requires definition of the conventional inputs such as labor rates, material costs, machine rates, scrap and also the less easy to attain; tariffs, exit tax, monetary shifts, logistics etc. This process is called Engineered or "Bottoms-up" estimating.

For the full article, please click here.

10 Best Practices for Design From the Design Profit Silver Book

Each issue of The Munro Report will feature one of Munro's Design Principles. Implementation of these principles will help maximize the profitability of your product through its design.

Lean Design Principles - 09

Question Servicing And Simplify Or Eliminate Packaging

Question Servicing – Is it better to design something that can be serviced? Or would it be better to be thrown away? Now, many companies would assume that building in some sort of serviceability would actually result in higher revenues or perhaps even be perceived as a value added benefit for the do-it-yourselfer. However, many times this is quite opposite to the case. For instance, Lead Acid batteries in cars used to be serviceable. This was a mess, and really not worth it for either the company or the consumer. The same can be said for all electronic modules in an automobile. Now, when these systems were in their infancy, there was a certain amount of serviceability (Like let’s say the Ford Pinto), but it was such a pain for auto owners that customer approval went into the dirt, not to mention, if something is serviceable, it is by definition not reliable or has quality issues – it’s made to be fixed. Now all electronics modules in autos – Engine Control Modules (ECM), Body Control Modules (BCM), etc. are throw away, because it is cheaper and more reliable to do so. This is why we now get 150,000 mile cars vs. Pinto Station Wagon which had to be constantly serviced. Warranty and quality issues cost both the consumer and the company time and money. If you want reliability you have to give up serviceability.

The people of Munro & Associates bring a wide and varied set of skills and experience to this organization. Although we are spread out from Tokyo to London and points all across the United Sates, this group of men and women share an additional common vision, which is to make our communities a better place.

This issue acknowledges Joe Feord and his family. The Feords have been volunteering their time to raise and breed dogs for the Leader Dogs® program in Rochester Hills, Michigan. They started in the program by housing and raising a yellow lab named Max who was to be placed in the program after one year. Now the Feords have taken in Reese, a black lab breeder stock for Leader Dogs. Recently Reese gave birth to her second litter of twelve puppies. The puppies will be raised by the Feords for six weeks after which they will be turned over to the Leader Dogs. These puppies will be raised by other loving homes for one year and then placed into the program to become Leader Dogs for the Blind.

Founded by three Detroit area Lions Clubs members in 1939, Leader Dogs for the Blind provides dog guides to people who are blind and visually impaired to enhance their mobility, independence and quality of life. Each year, over 270 students attend their 26-day residential training program to be paired with a dog guide. This is a life-changing event that opens the doors to independence, safety and self-worth for many of our students.

Leader Dogs for the Blind operates on donations and does not charge the recipients of the dogs for their services. For more information visit http://www.leaderdog.org/

All photos and information copyright Munro & Associates, Inc. 2010

1749 Northwood Drive Troy, MI 48084

http://www.leandesign.com | Phone: +1 (248) 362-5110